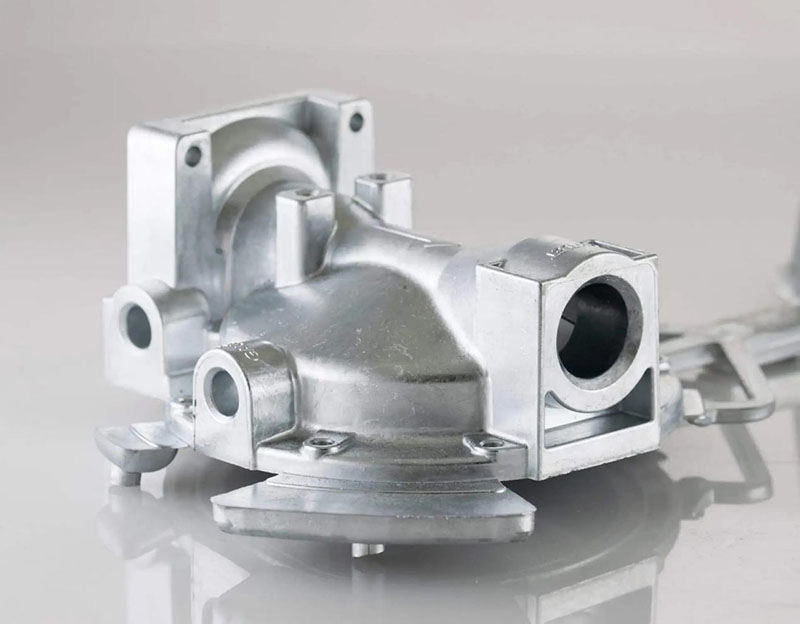

Teknic yog lub ntiaj teb tus thawj coj hauv kev tuag casting, nrog cov neeg siv khoom los ntawm cov tuam txhab tsim khoom lag luam loj mus rau kev lag luam tsheb los ntawm kev tsim lub tswv yim, rau kev tsim khoom thiab ntim khoom.

Peb muab zinc tuag casting los ntawm pwm tsim thiab kuaj, rau zinc tivthaiv kev tsim khoom, tiav, thiab ntim khoom los ntawm cov qauv tsim tshwj xeeb thiab tig lawv mus rau hauv cov khoom tiav.

Teknic yog cov tuam txhab zinc tuag casting tshaj 10 xyoo.Txij li thaum nws tau tsim, peb tau hloov zuj zus mus rau hauv lub ntiaj teb cov thawj coj siv nws cov thev naus laus zis wherewithal thiab cov kws tshaj lij los tsim cov khoom zoo tuag castings.Peb tsom mus rau qhov zoo thiab kev daws teeb meem hauv Suav teb.Lub hauv paus ntawm Zinc Moulding chaw tsim khoom.

Complex Shapes & Tight Tolerances

Zinc tuag casting tsim ntau kab noj hniav, cov duab complex thiab nyob rau hauv ze rau tolerances ntau dua lwm yam ntau lawm txheej txheem.Ntxiv nrog rau kev tsim cov ntim siab ua haujlwm ntawm qhov zoo ib yam, nws tsim cov cua sov rugged thiab hnav cov khoom tiv thaiv uas muaj qhov ruaj khov, thaum tswj kev ua siab ntev tshwj xeeb.

Cov txheej txheem tuag casting muab sijhawm rau cov neeg tsim qauv kom txuag tau cov nqi los ntawm kev sib koom ua ke rau hauv ib qho net-shaped tuag casting.Yog li, muaj peev xwm tshem tawm cov haujlwm thib ob xws li machining.Zinc tuag castings tau ua tiav tau tsim los ua cov kabmob (tshem tawm cov tooj liab tooj liab), rivets, thiab tuaj yeem muab pov rau hauv cov xov.Vim cov txiaj ntsig zoo no, tuag castings muaj nyob rau hauv ntau yam kev lag luam xws li tsheb, tsev kho vajtse, hluav taws xob, khoom ua si, thiab lwm yam.

Nws yuav tsum tau muab sau tseg tias kev lag luam tus qauv kam rau ua tau raws li thiab / los yog tshaj, yog tias tsim nyog rau kev tsim ntawm ib feem.Txawm li cas los xij, muaj ntau yam uas yuav tsum tau xav txog, xws li;cov duab ntawm ib feem, qhov twg ib tug feature nyob rau hauv lub cuab tam, dab tsi yog nws txoj hauj lwm nrog rau lwm yam nta ntawm ib feem thiab yog hais tias koj yog dimensioning hla txoj kab parting.Thaum xav txog cov cuab yeej siv lub neej thiab tus nqi, nws yog qhov kev xyaum zoo tshaj plaws los tso cai rau siab dav thiab tsim qauv ntawm thaj chaw uas tsis haum, daim ntawv lossis kev ua haujlwm thiab kom nruj rau qhov kev zam tsuas yog hauv thaj chaw uas tsim nyog.

Peb zine tuag casting ntau qhov loj los ntawm 100 tuj mus rau 300 tuj, ua zinc tuag casting Cheebtsam rau cov khoom siv qis lossis siab ntim ntau lawm.Peb tuaj yeem ua zinc kub chamber tuag casting, aluminium-zinc kub lossis txias chamber siab tuag casting, kuj aluminium tuag casting.Kev soj ntsuam cov txheej txheem, xovxwm sab duab, neeg hlau, khiav simulation, perpetual tooling thiab cov cuab yeej tu cov kev pab cuam yog siv los mus cuag cov cuab yeej lub neej, txuag nqi, sij hawm, thiab muab siab zoo tuag castings.Los ntawm ib feem conception thiab meej prototyping, mus assembling tiav cov khoom.

Zinc Alloys

Peb yog ib tug thawj coj nyob rau hauv manufacturing rau tuag casting nyob rau hauv Suav teb.Peb cov kws cob qhia Metallurgists kom ntseeg tau tias tag nrho cov alloys ua tau raws li cov kev qhia tshwj xeeb los ntawm kev tshawb xyuas tshuaj lom neeg thiab lub cev tsis tu ncua.

Peb cov alloys muaj xws li:

Zinc: Zamak 3, 5, thiab 7.

Zinc-Aluminium: ZA-8, ZA-12, thiab ZA-27.

Zinc alloys yog qhov yooj yim rau kev kub siab diecast.Lawv muab cov ductility siab, cuam tshuam lub zog, thiab tuaj yeem ua tau yooj yim plated.Zinc alloys muaj qhov qis qis dua li cov txhuas uas tuaj yeem pab txhim kho lub neej tuag.

ZA alloys yog zinc-based tuag casting cov ntaub ntawv uas muaj cov ntsiab lus txhuas ntau dua li cov qauv zinc alloys.Cov alloys no muaj cov yam ntxwv siab zog kuj siab hardness thiab zoo bearing zog.

Zinc Mould Flow Test

Teknic siv thoob ntiaj teb lees paub CAM simulation thev naus laus zis los txhim kho cov cuab yeej tsim thiab zinc casting zoo.

CAM simulation muaj peev xwm muab kev nkag siab zoo ntawm zinc txhaj pwm filling, solidification, mechanical zog, thermal stresses thiab distortions.Tag nrho cov ntawv qhia zaub mov-tsav nrog kev sib xyaw ua qauv qauv, CASD interfaces, thiab cov ntaub ntawv dav dav, CAM muab cov kev daws teeb meem tiav rau kev tsim, tsim khoom, thiab cov chaw ua haujlwm zoo.

Hlau Txhaj Pwm Castings

CNC Machining thiab Hog-outs

Direct Hlau Laser Sintering (DMLS)

P-20 Tooling

ZINC NTAU NTAU TSHAJ

Teknic yuav tswj xyuas cov neeg siv khoom tiav kom ntseeg tau tias cov khoom ua tau raws li qhov tshwj xeeb hauv lub sijhawm thiab tus nqi zoo.

Peb cov zinc nto finishing suav nrog:

Powder Txheej (daim ntawv thov electrostatic)

Cov xim ntub dej

Chromate

E-coat

Electroless Nickel

Chrome

Silk Screening thiab Stenciling

EMI / RFI Kev Tiv Thaiv

Deg Conditioning (steev thiab hlaws blasting)